ipTEST develops and delivers its products via a dedicated and engaged team of partners who we work with to dovetail our processes into theirs to ensure excellent communication and responsivity.

We rely on our partners and suppliers throughout the UK and Europe to ensure the efficiency of the whole supply chain to our customers. Recognising this dependence, we have invested heavily in stock, test equipment, processes and training to ensure our partners feel they are an integral part of ipTEST.

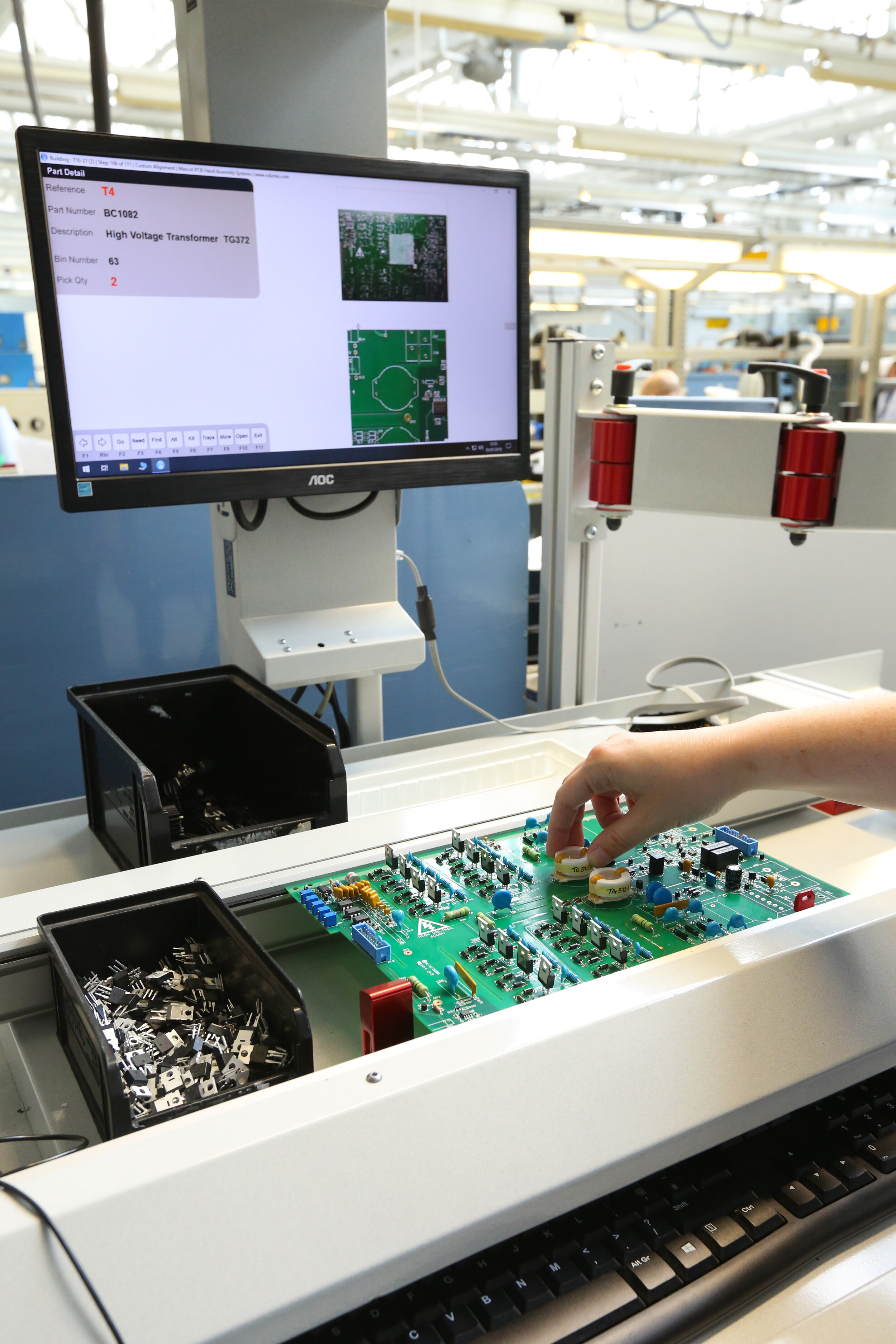

Our manufacturing partners are responsible for delivering boards, cabinets and sub-assemblies manufactured and tested according to our standards. The various sub-systems are then delivered to ipTEST for final assembly. Before shipping, we subject our systems to three levels of testing - diagnostics, standard applications tests and any customer-specific application tests. Then we foil-wrap each system in a vacuum packed foil bag to avoid any problems with air freight and humidity before finally crating in FSC certified crates.

Below are some of the key stages in the assembly of one of our systems.